Jump to

Attributes

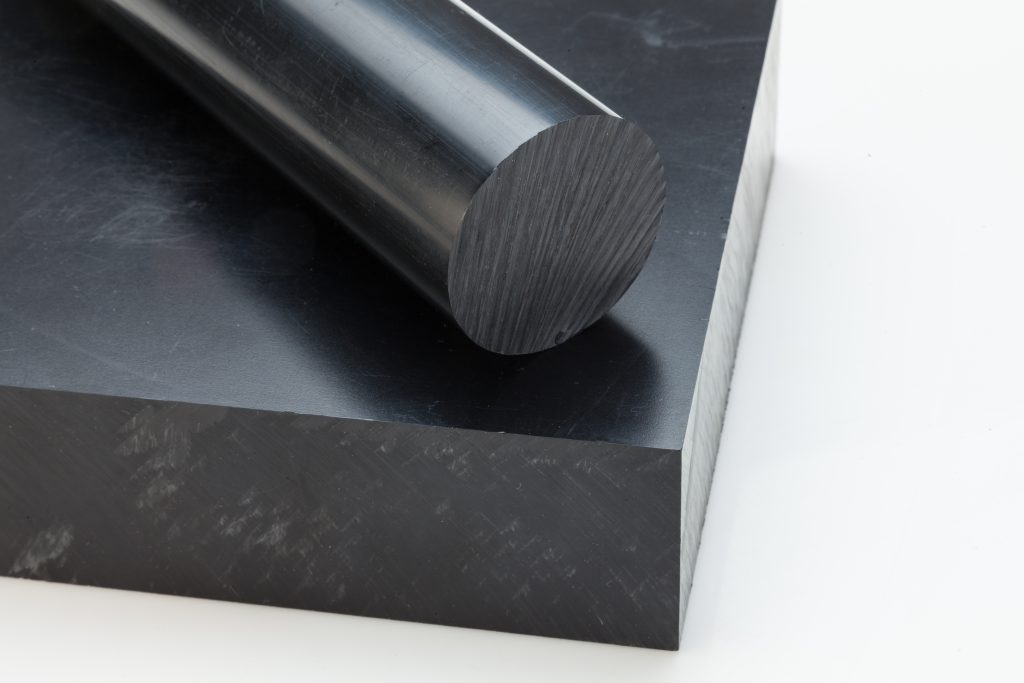

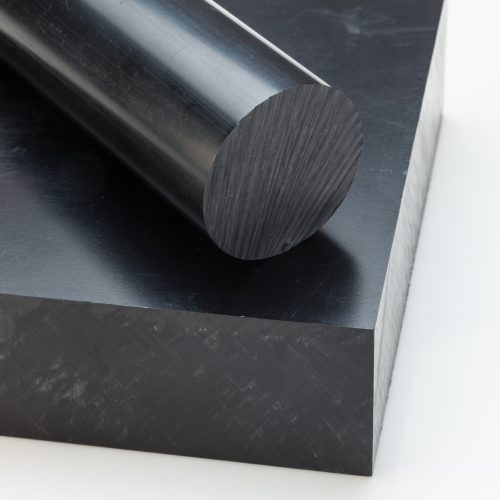

Norylux modified Poly Phenylene Oxide (PPO) is a high-strength, amorphous, engineering plastic with outstanding mechanical, thermal, and electrical properties. Low moisture absorption and low coefficient of thermal expansion make Norylux one of the most dimensionally stable thermoplastics available.

Norylux PPO is widely used for electrical housings and structural components since it has excellent insulating properties, flame resistance, strength and stiffness, and dimensional stability over a wide range of service temperatures. Norylux is often selected for fluid handling applications since it has low moisture absorption and hydrolytic stability. Norylux machines easily and may be fabricated into complex shapes with close tolerances. Norylux is also easy to weld and glue, and it provides good adhesion to paints, inks and other decorative coatings.

Westlake Plastics extrudes and compression molds unfilled and flame-retardant products and compression molds glass reinforced and glass/mineral filled products.

Norylux™ Key Properties:

- Dimensional Stability

- Low Moisture Absorption

- Good Strength and Stiffness Over a Wide Range of Service Temperatures

- Good Impact Resistance

- High Dielectric Strength

- Excellent Flammability Rating (UL94 V-1 @ .058" Thick)

- Easy to Fabricate, Paint, Weld, and Glue

The Norylux™ Lineup

Norylux™

modified polyphenylene oxide

- Low moisture absorption

- Dimensional stability

- High dielectric strength

1 Colors

Norylux™ GF

modified polyphenylene oxide

- Low moisture absorption

- Dimensional stability

- High strength & stiffness

1 Colors