Westlake Plastics is excited to once again be exhibiting at AAOS 2023 in Las Vegas, Nevada. The conference runs from March 7th to the 11th and the trade show exhibit is March 8th to 10th. The AAOS Annual Meeting is the world’s premier event for orthopedic surgeons to gather and to learn about the latest developments in surgical technology and research. As a material supplier to many of the industries device, equipment, and implant manufacturers, Westlake Plastics is proud to participate and to showcase both our latest innovations as well as to reinforce our long-term performers.

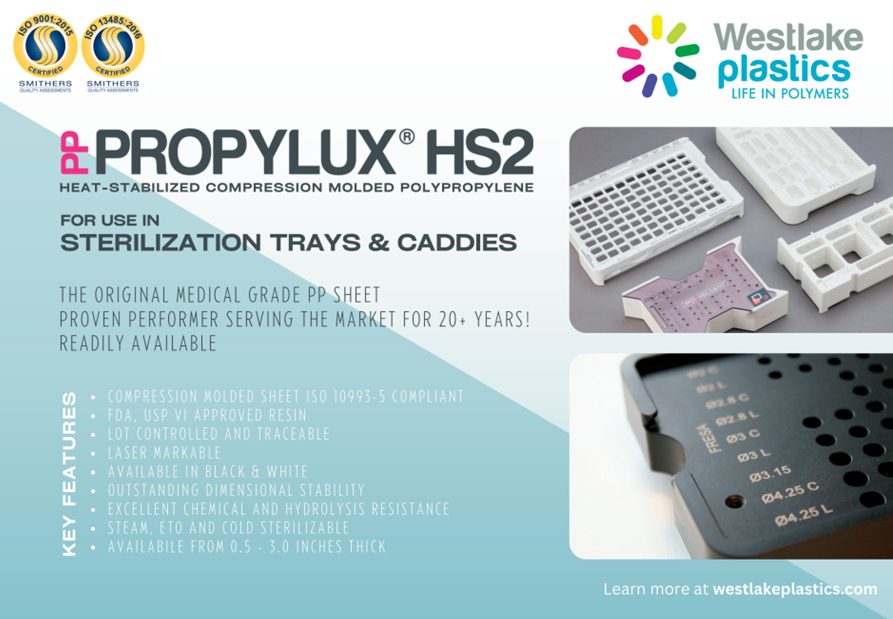

Featured Product #1 – PROPYLUX HS2

One such performer is PROPYLUX HS2, a heat-stabilized compression molded polypropylene sheet engineered for use in sterilization caddies. PROPYLUX HS2 has been serving the marketplace for over 20 years and has a proven record of success. To learn more about PROPYLUX HS2 properties and sizing options, visit https://www.westlakeplastics.com/products/propylux-pp-hs2/.

Featured Product #2 – PROPYLUX HS

PROPYLUX HS is a heat-stabilized polypropylene engineered for use in many medical device applications such as

- Sterilization containers & brackets

- Surgical instrument handles

- Impactor devices

- Joint replacement sizing trial devices

To learn more about PROPYLUX HS properties, size, and color options, visit https://www.westlakeplastics.com/products/propylux-pp-hs/.

Featured Product #3 – RADEL

RADEL is an amorphous transparent high performance polyphenylsulfone. Like PROPYLUX HS, RADEL is engineered for use in many medical device applications such as

- Sterilization containers & brackets

- Surgical instrument handles

- Impactor devices

- Joint replacement sizing trial devices

To learn more about RADEL properties, size, and color options, visit https://www.westlakeplastics.com/family/radel/.

Featured Product #4 – LENNITE

LENNITE is an ultra-high molecular-weight polyethylene (UHMW-PE) ram extruded bar stock that is made in accordance with ASTM specification F648 and International Standard ISO 5834-1. LENNITE has superb impact and wear, as well as high chemical and radiation resistance. Due to its extremely low coefficient of friction, its inherent lubricity minimizes friction resulting in a smooth, noiseless operation. This versatile engineering plastic with its superior tribological properties makes it ideally suited as a bearing counterface in orthopedic joint replacement systems for shoulder, hip, knee, and other extremity joint replacement procedures. To learn more about LENNITE properties and size options, visit https://www.westlakeplastics.com/family/lennite/.

If you will be attending the show, stop by booth #6446 to see the material live and to talk with the experts. We hope to see you there!

The Westlake Team