Attributes

Westlake Plastics offers a wide array of materials to satisfy the requirements of the most demanding applications in the chemical process industry. From polyolefin thermoplastics such as polypropylene and polyethylene, to fluoropolymers such as PVDF and ECTFE, to ketone-based products such as PEEK and PEKK and PPS we have the materials to suit the needs of chemical processing applications.

Chemical Process Key Properties:

- Chemical Resistance Over Broad Temperature Range

The Chemical Process Lineup

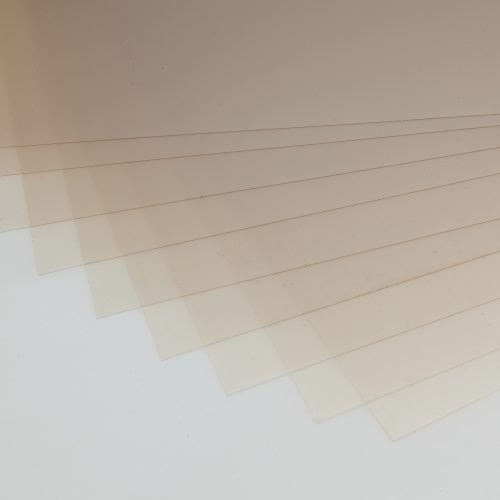

Amidelux™

- Transparency

- Impact resistance

- Chemical resistance

1 Colors

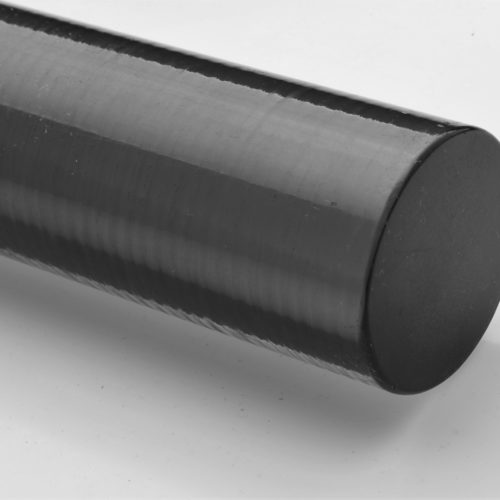

Arolux® PEEK WM

- Higher heat resistance

- Chemical resistant

- High strength

- High stiffness

1 Colors

Arolux® PEKK

- Highest Heat resistance

- Chemical resistant

- High strength

- High stiffness

1 Colors

Arolux® PPS

- High Heat resistance

- Chemical resistant

- High strength

- High stiffness

1 Colors

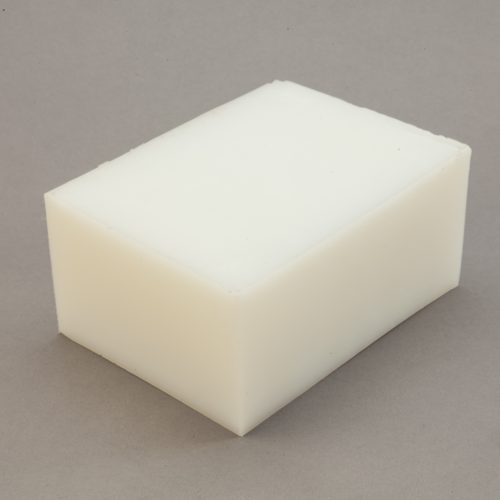

Ethylux™

- Chemical resistance

- Impact resistance

- Low moisture absorption

1 Colors

Fluorolux™

- Chemical resistance

- Heat resistance

- Flammability resistance

1 Colors

Kynar®

- Heat Resistant

- Biocompatibility

- Flammability Resistance

- Food Contact

3 Colors

Propylux™ DS

- Chemical Resistance

- Dimensional Stability

- Toughness/Impact Resistance

1 Colors

Propylux™ VF

- Impact resistance

- Chemical resistance

- Low Moisture absorption

1 Colors

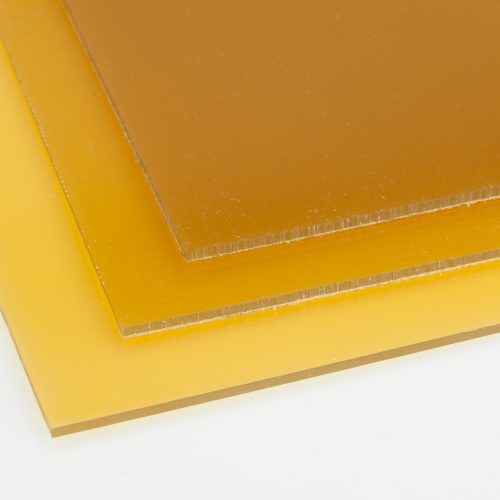

Tempalux®

- High heat resistance

- High strength and stiffness

- Good chemical resistance

- Inherently flame retardant

2 Colors

Tempalux® GF20

- High heat resistance

- High strength and increased stiffness

- Good chemical resistance

- Inherently flame retardant

1 Colors

Tempalux® GF30

- High heat resistance

- High strength and increased stiffness

- Good chemical resistance

- Inherently flame retardant

1 Colors

Thermalux® PESU

- High heat resistance

- High strength and stiffness

- Good chemical resistance

1 Colors

Thermalux® PPSU

- Highest heat resistance

- High strength and stiffness

- Good chemical resistance

- Inherently flame retardant

2 Colors

Thermalux® PSU

- Good heat resistance

- High strength and stiffness

- Good chemical resistance

- Biocompatible

1 Colors

Ultra Ethylux®

- Chemical resistance

- Impact resistance

2 Colors

Ultra Ethylux® FDA

- Food Contact Safe

- Chemical Resistance

- Impact Resistance

- High Stiffness

2 Colors

"Westlake Plastics is excited to partner with companies like Arkema and Evonik to bring new materials such as Arolux PEKK and Amidelux PA that provide additional materials solutions for demanding chemical exposure environments."

Jason Ross, Westlake VP of Sales and Marketing